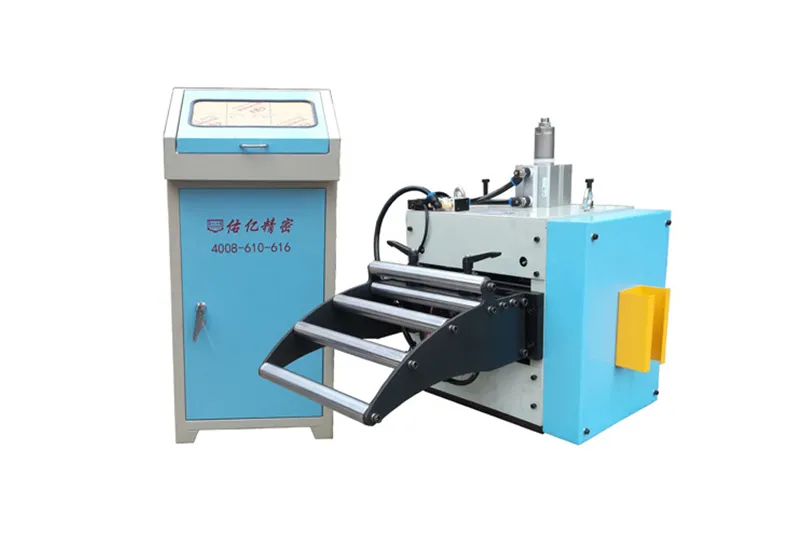

NC Servo Feeder for High-Accuracy Press Feeding

YouYi's NC Servo Feeder is a precision coil and strip feeding solution engineered for modern stamping and press automation lines. Driven by a high-performance servo system and a closed-loop encoder feedback, the feeder delivers repeatable feeding accuracy (typical ±0.02 mm; short-distance accuracy ≤ ±0.01 mm), high responsiveness and flexible feed-length programming. Typical configurations support material widths from 100 mm to 600 mm and thickness ranges from 0.1 mm up to 6.0 mm with servo power options from 2 kW to 5 kW depending on model.

Designed for integration with decoilers, straighteners and press transferring systems, the NC Servo Feeder supports mechanical and pneumatic release modes, optional zig-zag feeding for circular blanks, and multiple accessory options (measuring wheel, remote pendant, anti-backlash gearbox). Standard control includes a PLC + touchscreen HMI with EtherCAT/RS485 communication available on request. For high-speed stamping lines and micro-part application where positional accuracy and repeatability matter, this feeder reduces scrap, improves die life, and shortens setup time compared to pneumatic or purely mechanical rollers.

· Engineered for high-speed, high-precision continuous stamping operations.

· Optimized for micro parts and thin-strip high-speed feeding.

· Seamlessly integrates with smart systems for fully autonomous material handling.

NC Servo Feeder — Specifications

| Model | Max Width (mm) | Thickness Range (mm) | Max Line Speed (m/min) | Feeding Accuracy | Servo Power (kW) | Typical Release Type | Net Weight (kg) |

|

|---|

| NC-100 (Light) | 100 | 0.1 – 3.0 | 0 – 20 | ±0.02 mm (short-distance ≤ ±0.01 mm) | 2.0 (typ.) | Mechanical / Pneumatic (optional) | ~180 (replace with factory value) |

|

| NC-300 (Medium) | 300 | 0.1 – 3.0 | 0 – 20 | ±0.02 mm (short-distance ≤ ±0.01 mm) | 3.0 (typ.) | Pneumatic / Mechanical | ~320 (replace with factory value) |

|

| NC-600 (Thick Plate) | 600 | 0.1 – 6.0 | 0 – 15 | ±0.02 mm (short-distance ≤ ±0.01 mm) | 5.0 (typ.) | Pneumatic / Mechanical / Zigzag | ~620 (replace with factory value) |

|

NC Servo Feeder specs

NC Servo Feeder Manufacturer

As a professional NC servo feeder manufacturer, we focus on reliable design, stable performance, and practical engineering solutions. From standard models to customized configurations, we provide feeding equipment that meets the demands of global metal stamping manufacturers.

Technical support and overseas service experience enable us to support customers throughout installation, commissioning, and production operation.

Servo Control System & Feeding Accuracy

Closed-Loop Servo Control

Our NC servo feeder adopts a closed-loop servo control system combining a servo motor and high-resolution encoder. The system continuously monitors feeding position and corrects deviations in real time, ensuring stable and precise feeding even during high-speed press cycles.

High Feeding Accuracy & Repeatability

With optimized control algorithms and rigid mechanical structure, the feeder delivers excellent repeatability and stable feeding accuracy. This performance is essential for progressive dies, multi-station stamping, and high-precision metal forming operations.

YouYi NC Servo Feeder – Applications in Stamping

YouYi NC Servo Feeders deliver high precision, speed, and stability across a wide range of stamping applications, including:

► Electronic hardware stamping

► Automotive parts stamping

► Home appliance structural parts stamping

► Precision metal stamping

► Motor stator and rotor stamping

► Thin sheet and stainless steel stamping

► Precision terminal and connector stamping

► Large structural part stamping

► High-precision thin metal stamping